Electromagnetic flowmeter FELD350 works based on Faraday's Law of Electromagnetic Induction and is an inductive instrument that measures the volume flow of conductive media.

Electromagnetic FlowmeterFELD 350Type It works based on Faraday's Law of Electromagnetic Induction and is an inductive instrument that measures the volume flow of conductive media. In addition to measuring the volume flow rate of general electrical conductors, it can also be used to measure the volume flow rate of strong corrosive liquids such as strong acids and strong bases, and uniform liquid-solid two-phase suspended liquids such as slurry, pulp, and pulp.

FELD 350Product characteristics

◆ Not affected by changes in fluid density, viscosity, temperature, pressure and conductivity

◆ No flow blocking parts, no pressure loss, and lower requirements for straight pipe sections

◆ Good corrosion resistance and wear resistance

◆ Strong anti-interference ability, reliable measurement and high accuracy

◆ Adopt 16-bit embedded microprocessor, fast computing speed, high precision, and low power consumption

◆ Adopt SMD devices and surface mount (SMT) technology for high circuit reliability

◆ There are no moving parts or obstructing flow parts in the pipeline, and there is almost no additional pressure loss during measurement.

◆ The range can be modified online on site according to the actual needs of users

◆ Optional digital communication signal output such as RS485, RS232, Hart and Modbus Profibus-DP

◆ With self-test and self-diagnosis functions

Electromagnetic Flowmeter FELD 350 instrument applications

Widely used in: petroleum, chemical industry, metallurgy, light textile, papermaking, environmental protection, food and other industrial sectors and municipal, water conservancy, river dredging and other fields.

Technical parameters of FELD 350

Model | FELD 350 |

Public Weigh mouth diameter ( mm ) | PTFE lining: (DN10-DN600) |

range ratio | 150:1 |

Repeatability | ±0.1% |

Precision. | ±0.3%,±0.5% |

Operating temperature | Neoprene rubber: -20~+60℃ Fluorosilicone rubber: -20~+90℃ |

Work pressure | DNI0~DN50≤2.5 MPa DN65~DN250≤1.6 MPa |

Ambient temperature | -25~+60℃ |

ambient humidity | 5%~95% |

Velocity range | 0.1~15 m/s |

conductivity range | ≥5μs/cm |

signal output | 4~20 mA(Max.750Ω) ·Pulse/frequency, alarm output |

communication output | RS485 ·MODBUS protocol·HART protocol·Profibus-DP protocol |

Power supply | 90~260 VAC,45-63 Hz, optional 11~40 VDC |

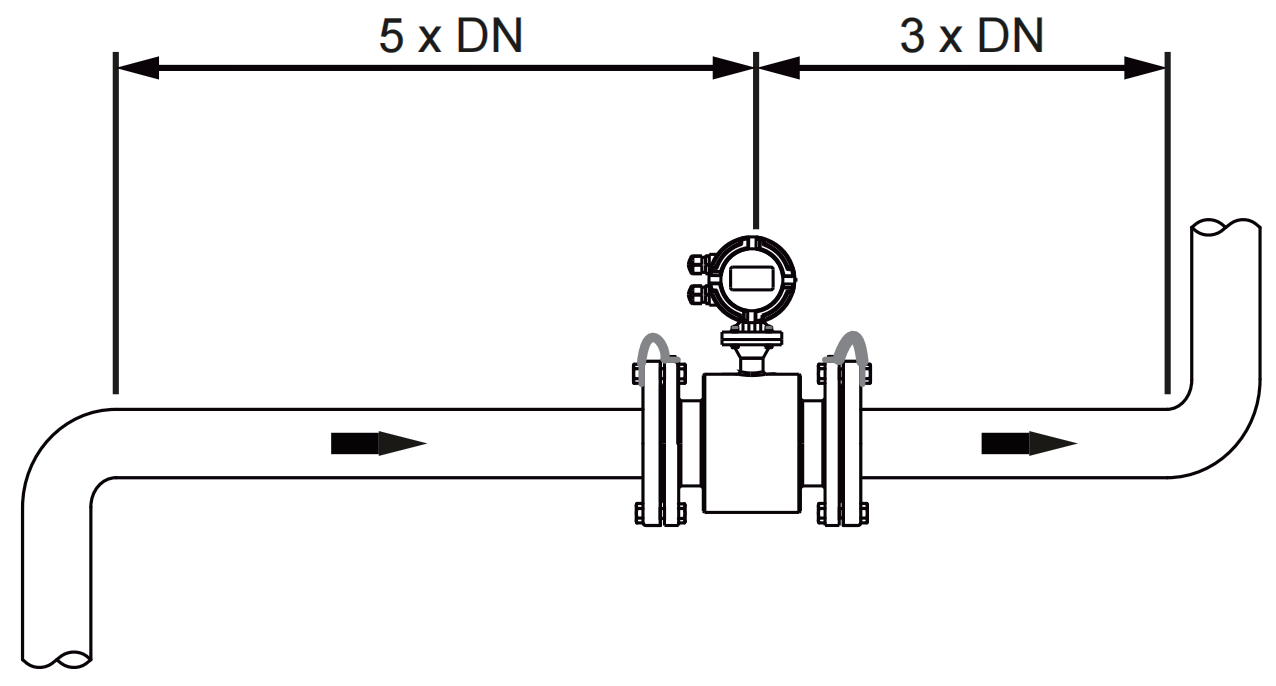

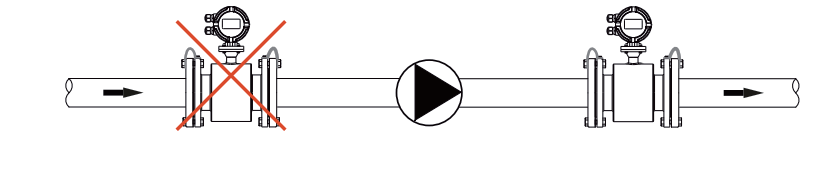

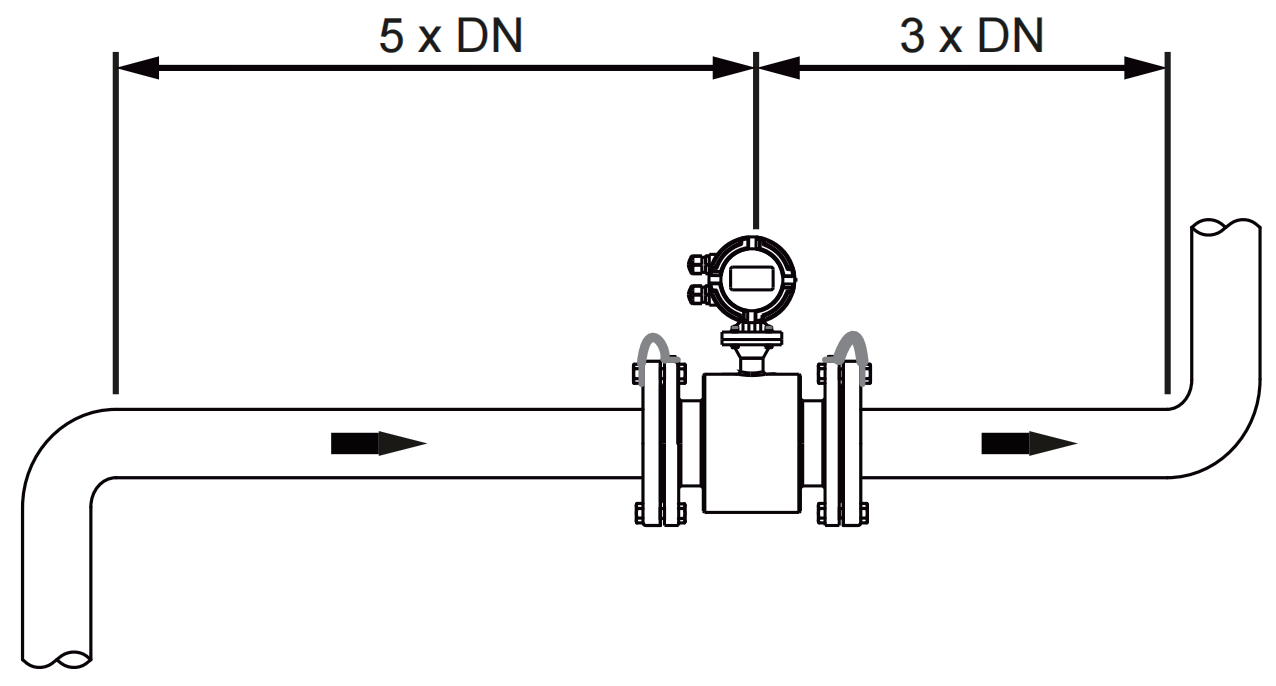

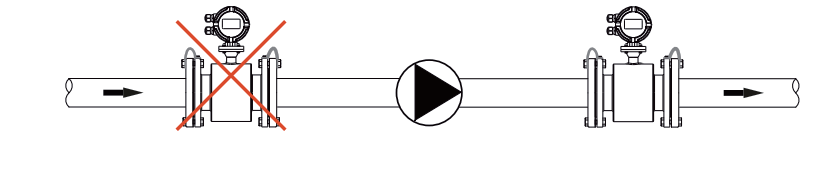

straight pipe length | upstream≥5 DN, downstream ≥2 DN |

Connection mode | Flange connection, threaded connection, clamp connection |

explosion-proof grade | Exmd I CT5(customized) |

Protection grade | IP65、IP67、IP68 |

FELD 350 Liner and Electrode Selection

Electromagnetic flowmeters are widely used in various industries, and the selection of their materials is a very important issue. Since in electromagnetic flowmeters, only the inner part of the electrode and measuring tube is in contact with the medium, the electrode material and lining should be reasonably selected according to the different properties of the medium, and the pipeline pressure and protection level should also be taken into account. For example: petroleum, chemical industry, metallurgy, light textile, papermaking, etc.

lining material

material | Name | referred to as | performance | Temperature | Applicable liquids | Applicable caliber |

Oaks glue | polychloroprene rubber | CR | Medium wear resistance and corrosion resistance from general low-concentration acid, alkali and salt | <60℃ | Tap water, industrial water, seawater | DN50~DN2000 |

polyurethane rubber | PU | Excellent wear resistance, poor acid and alkali resistance | <60℃ | Pulp, pulp and other slurry | DN25~DN500 | |

polyfluorosilicone rubber | FVMQ | Excellent wear resistance, high tearing force, high temperature resistance, no corrosion resistance | <200℃ | high temperature water | DN25~DN1200 | |

fluorine plastic material | polytetrafluoroethylene | PTFE | stable chemical properties ·Resistance to boiling hydrochloric acid, sulfuric acid, aqua regia, and concentrated alkali | <120℃ | Highly corrosion-resistant acid, alkali and salt liquids | DN10~DN1600 |

fluorinated ethylene propylene(Teflon) | F46(PEP) | Chemical properties equivalent toPTFE has better negative pressure resistance and tensile strength than PTFE | <200℃ | Corrosive acid, alkali and salt liquids | DN10~DN400 | |

Copolymers of tetrafluoroethylene and perfluoroalkyl vinyl ethers | PFA | Chemical properties equivalent toF46 has better negative pressure resistance and tensile strength than F46 | <200℃ | Corrosive acid, alkali and salt liquids | DN10~DN400 |

electrode material

material | corrosion resistance(Scope of application) |

316L | 1. Domestic water, industrial water·raw water. Well water, urban sewage |

Hastelloy AlloyB(HB) | 1. Non-oxidizing acids such as hydrochloric acid (concentration less than 10%) Not applicable: Nitric acid |

Hastelloy AlloyC(HC) | 1. Mixed acid and mixed solution of chromium acid and sulfuric acid Not applicable: Hydrochloric acid |

titanium(Ti) | 1.Salt, such as:(1)Chloride (chloride/magnesium/aluminum/calcium/ammonium/iron, etc.) Not applicable: Hydrochloric acid, sulfuric acid, phosphorus acid, (2)Sodium salt, potassium salt, ammonium salt, hypoaluminate, seawater Reducing acids such as acids 2. Concentration less than 50% potassium hydroxide, ammonium hydroxide, hydroxide barium alkali solution |

tantalum(Ta) | 1. Hydrochloric acid (concentration less than 40%) ·Dilute sulfuric acid and concentrated sulfuric acid (excluding fumanic acid) Not applicable: Alkali, oxyfluorine acid |

platinum(Pt) | Almost all acid, alkali, and salt solutions (including fuming sulfuric acid, fuming nitric acid) Not applicable: aqua regia, ammonium salt |

tungsten carbide | Pulp, sewage, resistant to interference from solid particles Not applicable: Inorganic acids, organic acids, oxides |

☞ note: while every effort isDue to the wide variety of media and its corrosiveness changes due to complex factors such as temperature, concentration, and flow rate, this table is for reference only, and users should make their own choices based on actual conditions. For general media, The corrosion manual can be consulted. For mixed acids and other complex media, corrosion tests of the materials to be selected should be done.

Installation diagram

Electromagnetic FlowmeterFELD 350Type It works based on Faraday's Law of Electromagnetic Induction and is an inductive instrument that measures the volume flow of conductive media. In addition to measuring the volume flow rate of general electrical conductors, it can also be used to measure the volume flow rate of strong corrosive liquids such as strong acids and strong bases, and uniform liquid-solid two-phase suspended liquids such as slurry, pulp, and pulp.

FELD 350Product characteristics

◆ Not affected by changes in fluid density, viscosity, temperature, pressure and conductivity

◆ No flow blocking parts, no pressure loss, and lower requirements for straight pipe sections

◆ Good corrosion resistance and wear resistance

◆ Strong anti-interference ability, reliable measurement and high accuracy

◆ Adopt 16-bit embedded microprocessor, fast computing speed, high precision, and low power consumption

◆ Adopt SMD devices and surface mount (SMT) technology for high circuit reliability

◆ There are no moving parts or obstructing flow parts in the pipeline, and there is almost no additional pressure loss during measurement.

◆ The range can be modified online on site according to the actual needs of users

◆ Optional digital communication signal output such as RS485, RS232, Hart and Modbus Profibus-DP

◆ With self-test and self-diagnosis functions

Electromagnetic Flowmeter FELD 350 instrument applications

Widely used in: petroleum, chemical industry, metallurgy, light textile, papermaking, environmental protection, food and other industrial sectors and municipal, water conservancy, river dredging and other fields.

Technical parameters of FELD 350

Model | FELD 350 |

Public Weigh mouth diameter ( mm ) | PTFE lining: (DN10-DN600) |

range ratio | 150:1 |

Repeatability | ±0.1% |

Precision. | ±0.3%,±0.5% |

Operating temperature | Neoprene rubber: -20~+60℃ Fluorosilicone rubber: -20~+90℃ |

Work pressure | DNI0~DN50≤2.5 MPa DN65~DN250≤1.6 MPa |

Ambient temperature | -25~+60℃ |

ambient humidity | 5%~95% |

Velocity range | 0.1~15 m/s |

conductivity range | ≥5μs/cm |

signal output | 4~20 mA(Max.750Ω) ·Pulse/frequency, alarm output |

communication output | RS485 ·MODBUS protocol·HART protocol·Profibus-DP protocol |

Power supply | 90~260 VAC,45-63 Hz, optional 11~40 VDC |

straight pipe length | upstream≥5 DN, downstream ≥2 DN |

Connection mode | Flange connection, threaded connection, clamp connection |

explosion-proof grade | Exmd I CT5(customized) |

Protection grade | IP65、IP67、IP68 |

FELD 350 Liner and Electrode Selection

Electromagnetic flowmeters are widely used in various industries, and the selection of their materials is a very important issue. Since in electromagnetic flowmeters, only the inner part of the electrode and measuring tube is in contact with the medium, the electrode material and lining should be reasonably selected according to the different properties of the medium, and the pipeline pressure and protection level should also be taken into account. For example: petroleum, chemical industry, metallurgy, light textile, papermaking, etc.

lining material

material | Name | referred to as | performance | Temperature | Applicable liquids | Applicable caliber |

Oaks glue | polychloroprene rubber | CR | Medium wear resistance and corrosion resistance from general low-concentration acid, alkali and salt | <60℃ | Tap water, industrial water, seawater | DN50~DN2000 |

polyurethane rubber | PU | Excellent wear resistance, poor acid and alkali resistance | <60℃ | Pulp, pulp and other slurry | DN25~DN500 | |

polyfluorosilicone rubber | FVMQ | Excellent wear resistance, high tearing force, high temperature resistance, no corrosion resistance | <200℃ | high temperature water | DN25~DN1200 | |

fluorine plastic material | polytetrafluoroethylene | PTFE | stable chemical properties ·Resistance to boiling hydrochloric acid, sulfuric acid, aqua regia, and concentrated alkali | <120℃ | Highly corrosion-resistant acid, alkali and salt liquids | DN10~DN1600 |

fluorinated ethylene propylene(Teflon) | F46(PEP) | Chemical properties equivalent toPTFE has better negative pressure resistance and tensile strength than PTFE | <200℃ | Corrosive acid, alkali and salt liquids | DN10~DN400 | |

Copolymers of tetrafluoroethylene and perfluoroalkyl vinyl ethers | PFA | Chemical properties equivalent toF46 has better negative pressure resistance and tensile strength than F46 | <200℃ | Corrosive acid, alkali and salt liquids | DN10~DN400 |

electrode material

material | corrosion resistance(Scope of application) |

316L | 1. Domestic water, industrial water·raw water. Well water, urban sewage |

Hastelloy AlloyB(HB) | 1. Non-oxidizing acids such as hydrochloric acid (concentration less than 10%) Not applicable: Nitric acid |

Hastelloy AlloyC(HC) | 1. Mixed acid and mixed solution of chromium acid and sulfuric acid Not applicable: Hydrochloric acid |

titanium(Ti) | 1.Salt, such as:(1)Chloride (chloride/magnesium/aluminum/calcium/ammonium/iron, etc.) Not applicable: Hydrochloric acid, sulfuric acid, phosphorus acid, (2)Sodium salt, potassium salt, ammonium salt, hypoaluminate, seawater Reducing acids such as acids 2. Concentration less than 50% potassium hydroxide, ammonium hydroxide, hydroxide barium alkali solution |

tantalum(Ta) | 1. Hydrochloric acid (concentration less than 40%) ·Dilute sulfuric acid and concentrated sulfuric acid (excluding fumanic acid) Not applicable: Alkali, oxyfluorine acid |

platinum(Pt) | Almost all acid, alkali, and salt solutions (including fuming sulfuric acid, fuming nitric acid) Not applicable: aqua regia, ammonium salt |

tungsten carbide | Pulp, sewage, resistant to interference from solid particles Not applicable: Inorganic acids, organic acids, oxides |

☞ note: while every effort isDue to the wide variety of media and its corrosiveness changes due to complex factors such as temperature, concentration, and flow rate, this table is for reference only, and users should make their own choices based on actual conditions. For general media, The corrosion manual can be consulted. For mixed acids and other complex media, corrosion tests of the materials to be selected should be done.

Installation diagram